Yingcheng Environmental Technology: Responding to Market Demand with Innovative Solutions

As a Guangdong-based company specializing in industrial dust removal and environmental protection technologies, Yingcheng Environmental Technology Co., Ltd. leverages years of technological expertise to launch a series of high-efficiency dust removal systems tailored to various scenarios. For example, in a case study for a large metal processing company, the company employed a combined "cyclone pretreatment + filter element deep purification" process, helping the company reduce dust emissions to below 5mg/m³ and reducing operating energy consumption by 20%, becoming an industry benchmark.

Furthermore, the company is actively exploring intelligent operation and maintenance models. By integrating IoT sensors, it enables real-time data monitoring, fault warnings, and remote debugging of dust removal equipment, significantly improving its stability and cost-effectiveness.

Future Outlook: A Balanced Approach to Green and Intelligent

With the deepening adoption of Industry 4.0 and the continued tightening of environmental protection policies, dust removal equipment is evolving towards greater efficiency, intelligence, and integration. The integration of intelligent manufacturing concepts not only improves the performance of the dust removal system itself but also enables companies to achieve integrated production and environmental management.

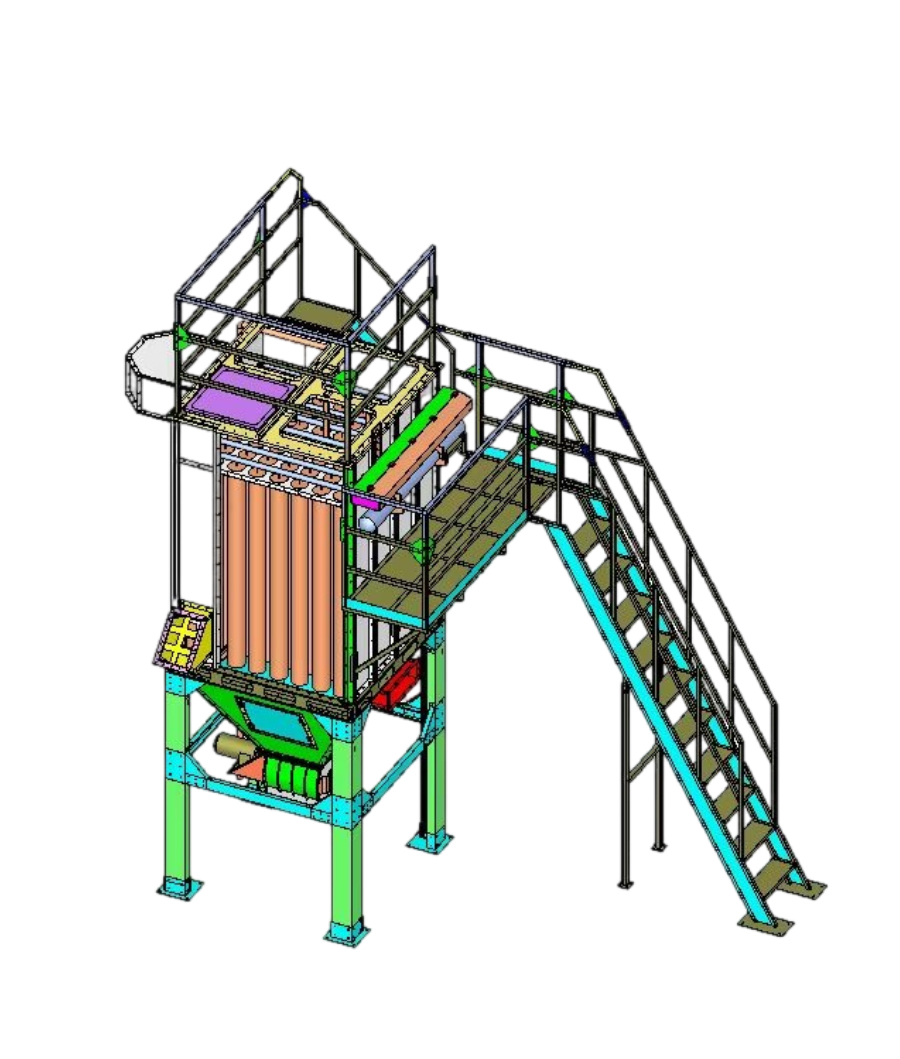

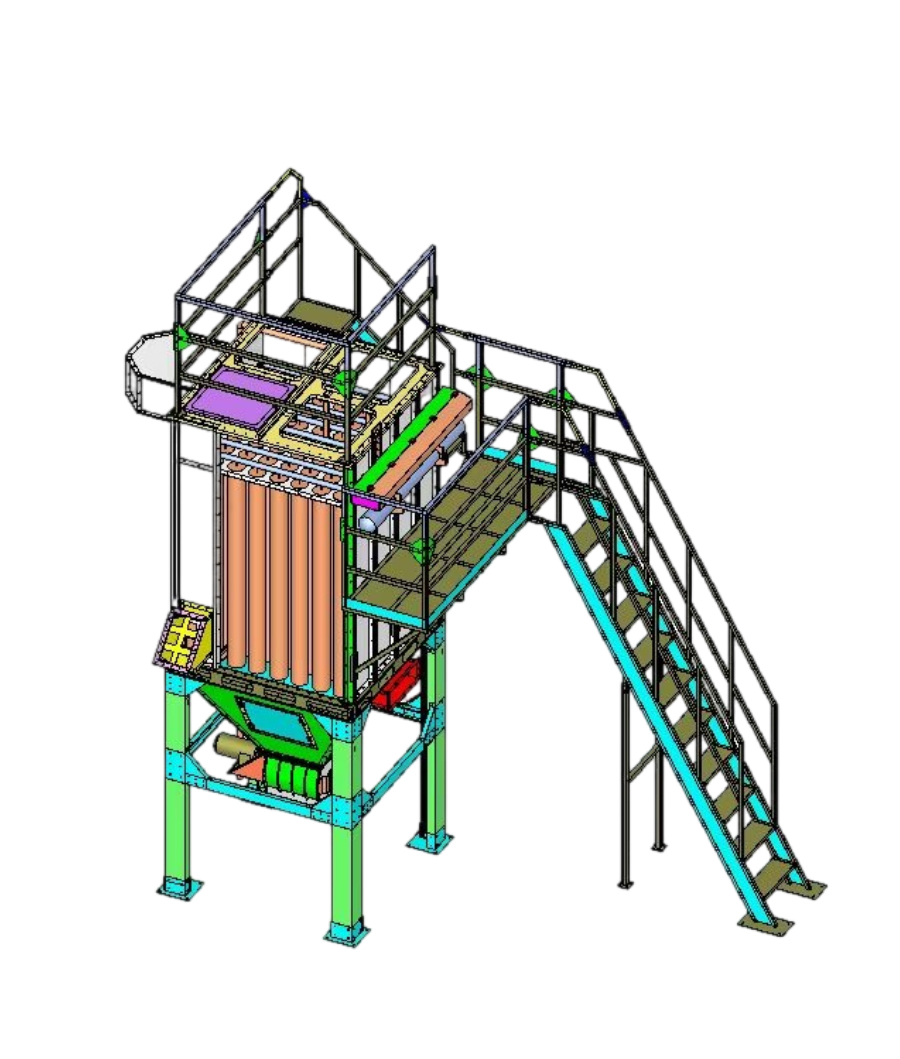

Filtration and Collection:

Dust-laden air enters the dust collector through the air inlet. After being distributed by the deflector, coarser dust particles fall directly into the hopper due to gravity or inertia. The air then slowly passes through the filter bags suspended within the dust collector, trapping the dust on the outer surface. The purified air then enters the filter bags and is ultimately discharged through the top exhaust port.

Dust Cleaning and Regeneration:

With the deepening of the Industry 4.0 concept and the continued tightening of environmental protection policies, dust collection equipment is evolving towards greater efficiency, intelligence, and integration. The integration of smart manufacturing concepts not only improves the performance of dust collection systems but also enables enterprises to achieve integrated production and environmental management.

Dust Collection:

The dust that is shaken off is collected in the hopper and then regularly discharged or recycled through devices such as dust removal valves.

Features:

With high dust removal efficiency (over 99.9%), large air volume, and stable operation, this device is widely used in industrial production for its high-efficiency dust removal.